How to level ceramic tiles

If you are going to renovate the floor or walls of any space and youwant to avoid the dreaded 'lippage' and protrusions of the tiles, properinstallation should be carried out.

When we choose ceramic tiles for the floor of a house or business premises, or as a wall covering, it is important that we pay proper attention to their correct installation. If we want to avoid the dreaded unevenness that can occur between the tiles, also known as 'lippage', we will have to choose a levelling system that will help us achieve this and ensure an optimal result. This will allow us to work faster and achieve better results within the space.

What is the purpose of the leveller?

It should be remembered that levelling systems are in no way a substitute for tile spacers. The leveller’s function is not to maintain the distance between the tiles, but to ensure that they remain adjoined and at the same height, thus avoiding the raising of the tiles and the appearance of lippage. To do this, we must follow a series of installation procedures and take into account some recommendations that will help us when renovating the floor or wall.

What kind of leveller is right for me?

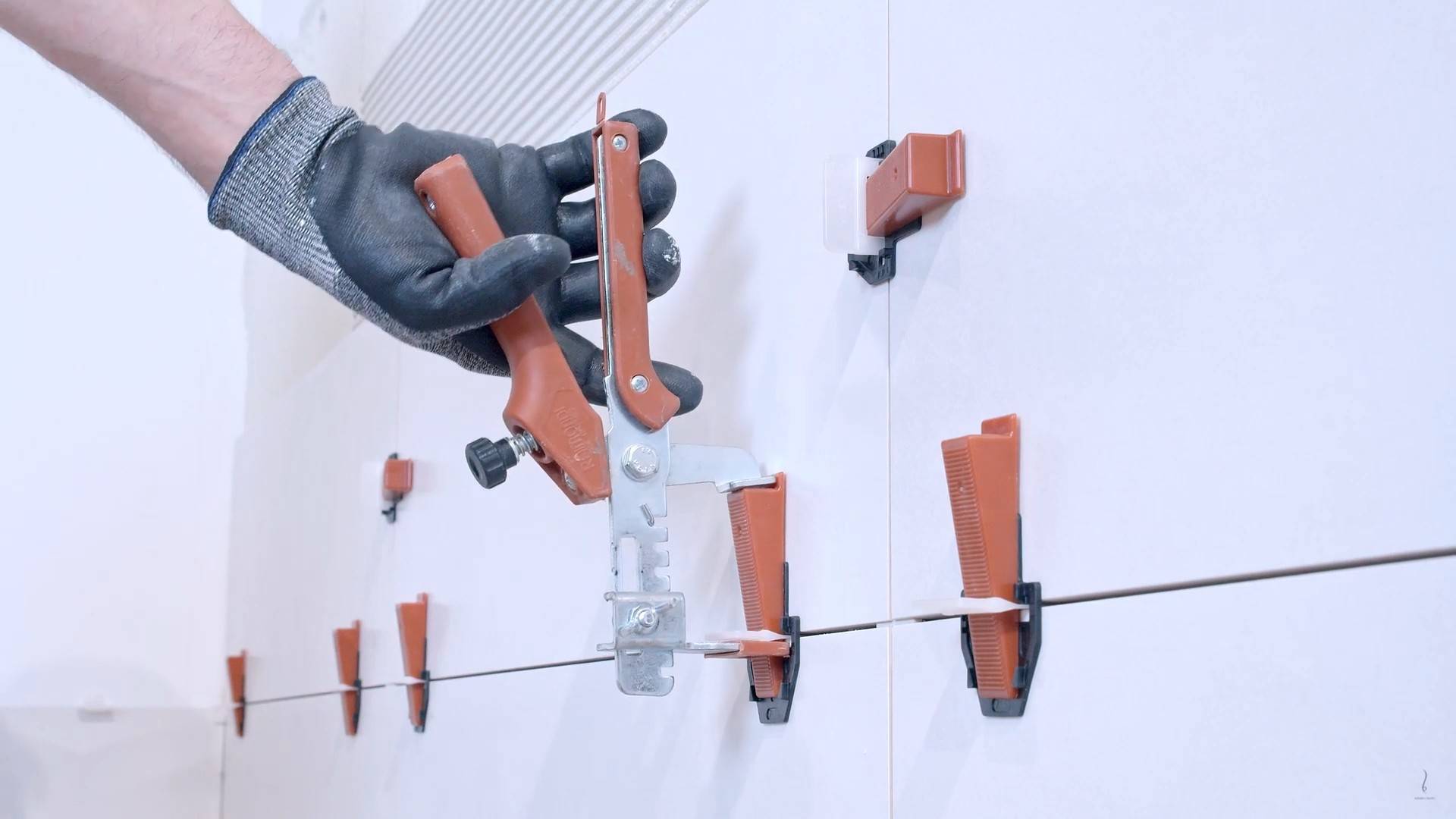

The levelling systems consist of the following elements: the levelling base itself, the tile nippers and, depending on the type, the wedge or the shim. There are also thread levellingsystems, which have a flange base for the insertion of another cylindrical base by means of a thread, without the need for tile nippers. Ideally, ask the manufacturer what the most suitable type for our tile is, taking into account the material and size.

Installation process

As with any ceramic installation, before starting work it is important to prepare the necessary materials (cement, tools, joints and levellers) and check that the flooring is in good condition.

• First, we spread the bonding cement on the floor or wall. The technique of double gluing, also smearing the rib of the piece, provides greater support to the tile, especially larger tiles.

• After placing the spacers between the pieces, we do the same with the alignment base on the surface of the tile. We knock the surface with a mallet to ensure the flatness.

• We put the flanges in place and adjust them using the nippers to create pressure, but not too much, so as not to cause damage to porous materials. Then we leave it to rest, following the drying times indicated.

• Finally, we remove the wedges by hitting them with a rubber mallet in the direction of the joint. Then, we clean up the excess, put them back together, and we’re done.

What recommendations should I follow?

1. The support surface must be in optimal condition. The surface where the flooring is to be laid must be cleaned and dried. The levelling systems do not correct inconsistencies in the base planimetry.

2. Double gluing for certain types of tile. According to official documents , in sizes from 30x30 centimetres, or in pieces with a very marked ridge. Do not leave gaps without adhesive.

3. Use a trowel size of between 6 mm and 10 mm. This will generate an even thickness of between 3 and 6 mm of putty, ensuring a better grip.

4. A regular thickness of the adhesive layer must be ensured, which should be at least 3 mm. Excessive thickness of the adhesive and poor application technique will create problems that are unrelated to the product.

5. The product should never be installed without a joint (this should measure at least 1.5 mm). The crosshead or spacer must be thicker than the levelling bridge.

6. Adhere to the drying times of the adhesive. The drying times are determined by the manufacturer and vary according to the size of the tile. Excess adhesive should be removed from the joints before it hardens.

7. It is recommended to hit the pieces lightly with a rubber mallet once the upper elements have been installed in order to release tension. For pieces that have a porous coating, or of little thickness, the installation of protective discs will help withstand that pressure.

8. When tapping to remove a piece, never aim for the wedgebut to the joint itself. It is better not to do this with your hands. On the most delicate surfaces, you can choose to use wedge-supported nippers.

In summary

The cost of the levelling system and the work involved is very low compared to the benefit they bring to a flooring installation. It means doing a much more automated and therefore faster job, as well as producing more even result. This translates into overall savings in time and possible subsequent costs. Levelling the ceramic tiles will allow us to boast beautiful and balanced walls and floors.